CEO

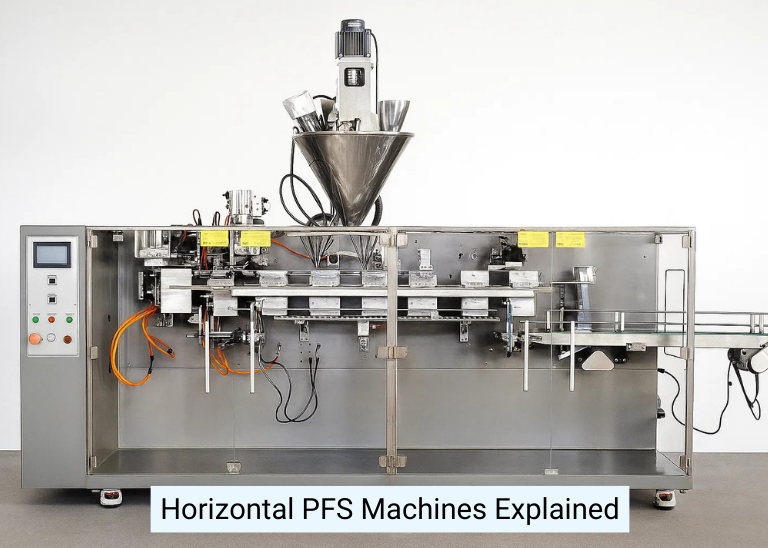

With over 10 years of experience in the packaging machinery industry, Rohan Thomas leads Fair Pack Machineries (Pvt) Ltd., a trusted manufacturer and exporter of advanced packaging solutions. The company specializes in automatic and semi-automatic filling, sealing, and conveyor systems designed for powders, granules, liquids, solids, and pastes. Under his leadership, Fair Pack serves diverse sectors including food, FMCG, pharmaceuticals, automobile, and industrial applications, providing machinery that combines innovation, reliability, and efficiency.

With a strong presence in both Indian and international markets, Fair Pack Machineries is known for its commitment to quality, customer support, and turnkey packaging solutions. Rohan focuses on driving growth through technology-driven products, global partnerships, and ensuring clients receive tailored solutions that meet international standards. His vision is to strengthen Fair Pack’s reputation as a global partner in packaging machinery while enabling businesses to scale with sustainable and cost-effective systems.

Click Here to Know More About the Company